Cathode stripping unit

As copper refining advances toward larger, highly automated processes, higher demands arise for equipment capacity and stability. Sanyou Tech continuously adopts and improves advanced global technologies, ensuring product innovation and reliability. By May 2025, it sold 62 cathode washing and peeling units and secured over 10 related patents.

- High peeling efficiency and clean production

- Intelligent thickness detection and adaptive control

- Multiple safety protections and self-healing of faults

- Flexible production line adaptation and remote operation and maintenance

Cathode copper stripping unit

Cathode copper stripping unit

In 2008, Sanyou Tech developed the cathode washing and peeling machine (CWSM), deployed at Huayou Cobalt. The 2010 second-gen CWSM reached 500 plates/hour and earned provincial new product and key equipment awards. In 2013, the third-gen robotic high-efficiency CWSM achieved 650 plates/hour, now used in projects like Zhongyuan Gold, Tongling Aolu, and Chifeng Jinjian.

- Cathode plate factory data management

Comprehensive data records enable full traceability of cathode plate information.

- Cathode plate usage status management

Full real-time tracking of cathode plates in the electrolytic workshop ensures smooth production flow.

- Dynamic detection correlation of flatness

Real-time flatness monitoring reduces labor and ensures optimal cathode plate condition.

- Correlation of copper surface quality inspection

Automated smart inspection replaces manual checks, ensuring optimal cathode copper quality.

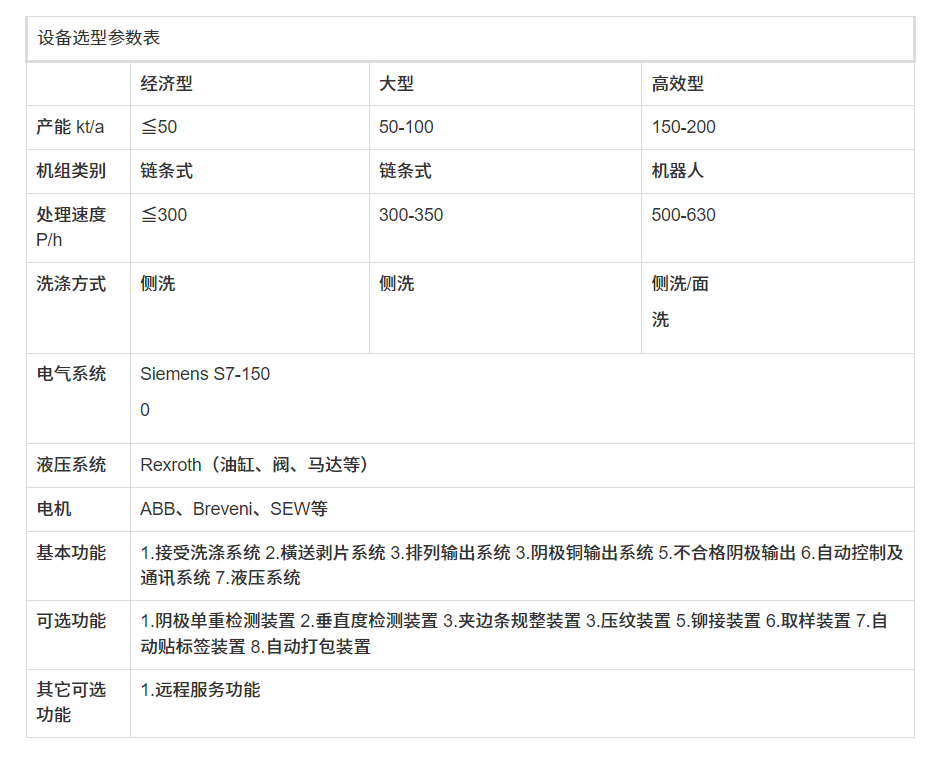

详细规格

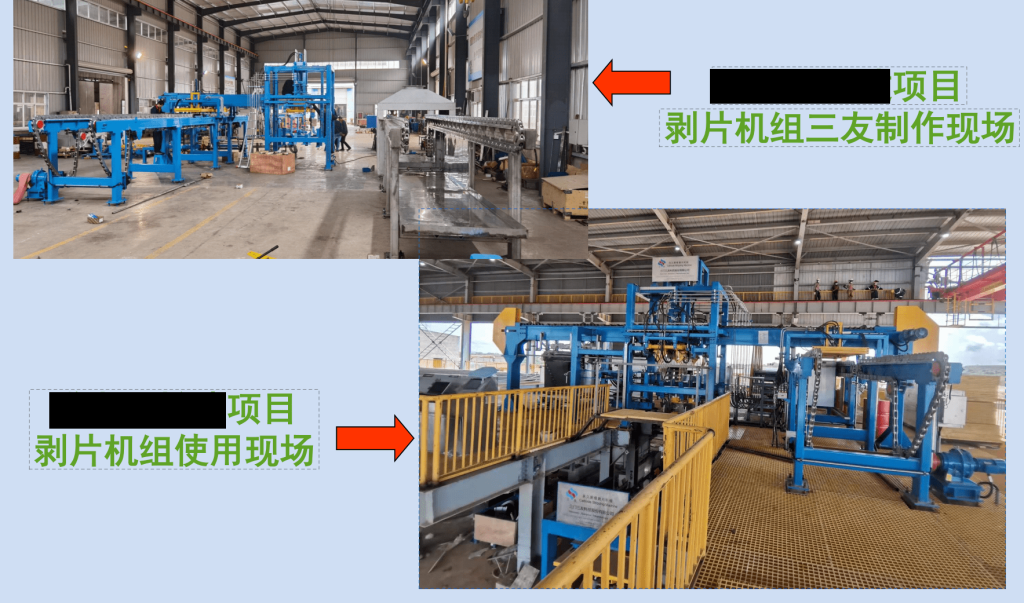

On-site fabrication 1

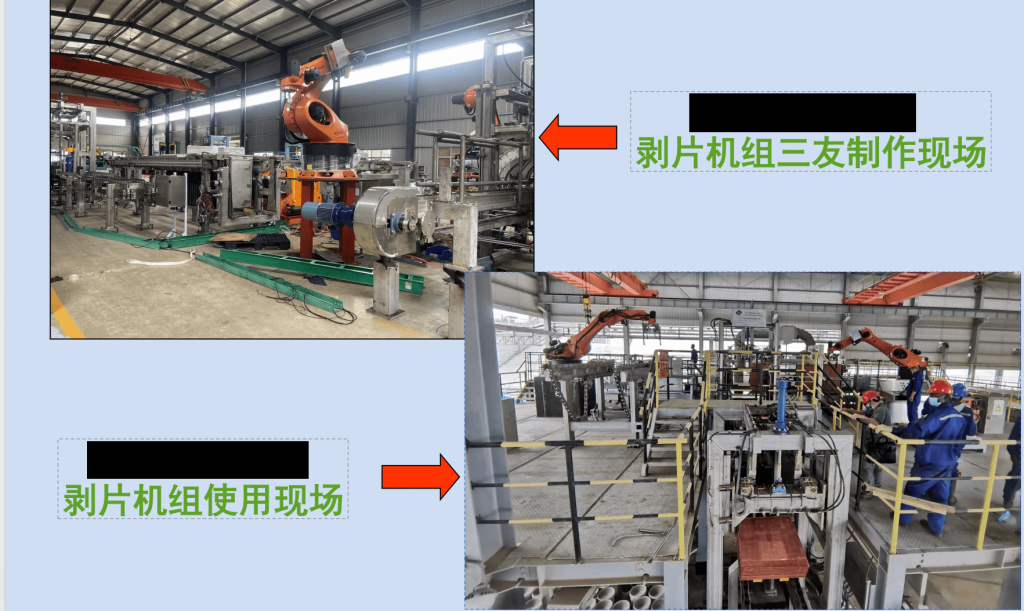

On-site fabrication 2

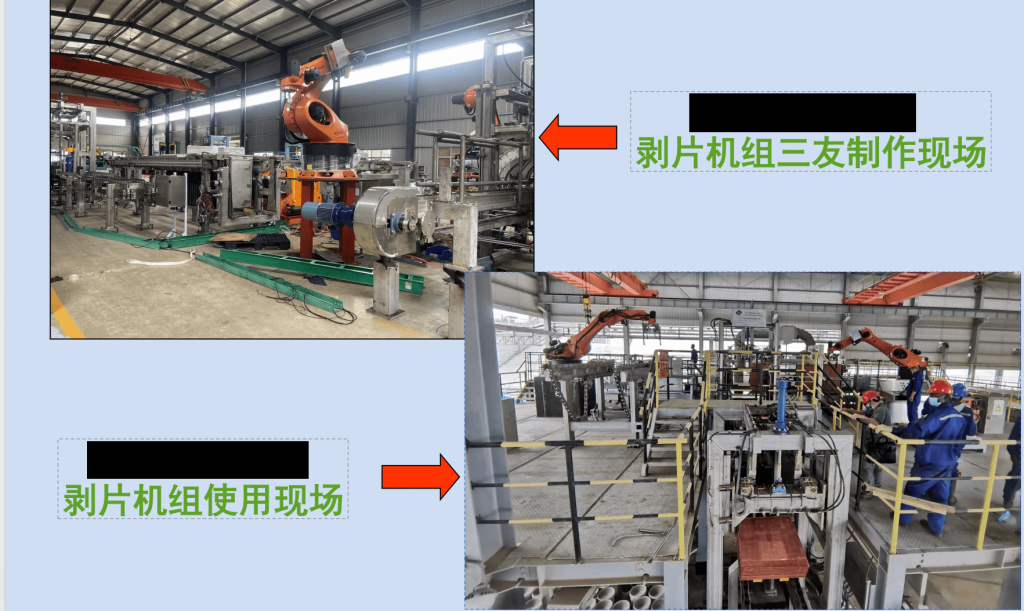

On-site fabrication 3