Precision purification filter

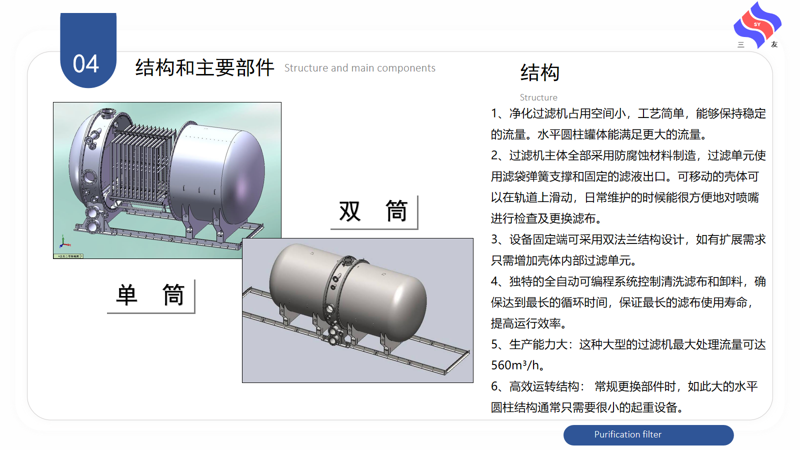

R&D on the purification filter began in 2007, completed in 2009. It was first used in 2011 at Zijin Copper’s 200,000-ton electrolytic project. In 2013, the dual-cylinder design debuted in Daye Nonferrous’s project, with a filtration area of 720m²/h. That year, it passed provincial new product certification and received software copyright registration. *Data from our design department.

- Precision filtration

- Efficient impurity removal

- Stable control of quality

Anode copper in wet copper refining contains various soluble and insoluble impurities. During electrolysis, electrolyte chemistry changes, affecting the process. Floating anode mud and fine solids cause more harm than ion discharge, creating fine particles on cathodes that grow and cause scrap. Thus, optimizing filtration in the electrolyte circulation system to reduce impurities is crucial.

In 2007, Sanyou Tech began developing a purification filter. Leveraging years of electrolysis equipment experience, it overcame technical challenges. By 2009, it produced a high-quality, low-cost, fully automated filter, breaking European and American monopolies in this field.

物理房间场景

虚拟空间场景