Residual pole washing unit

残极洗涤机组

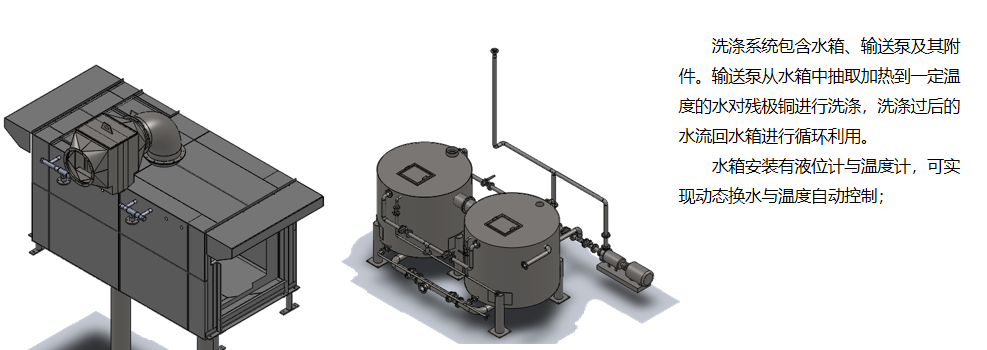

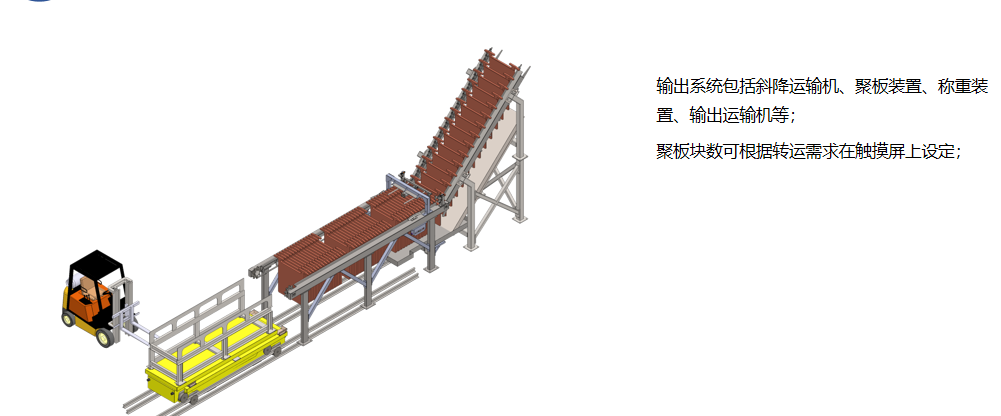

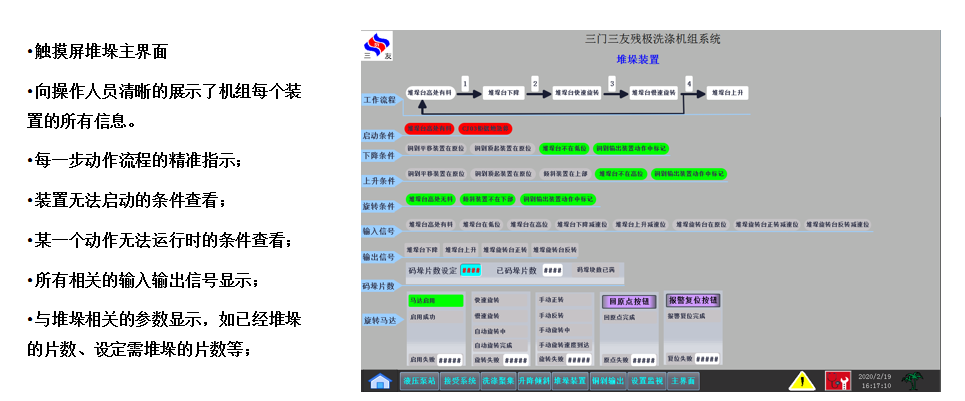

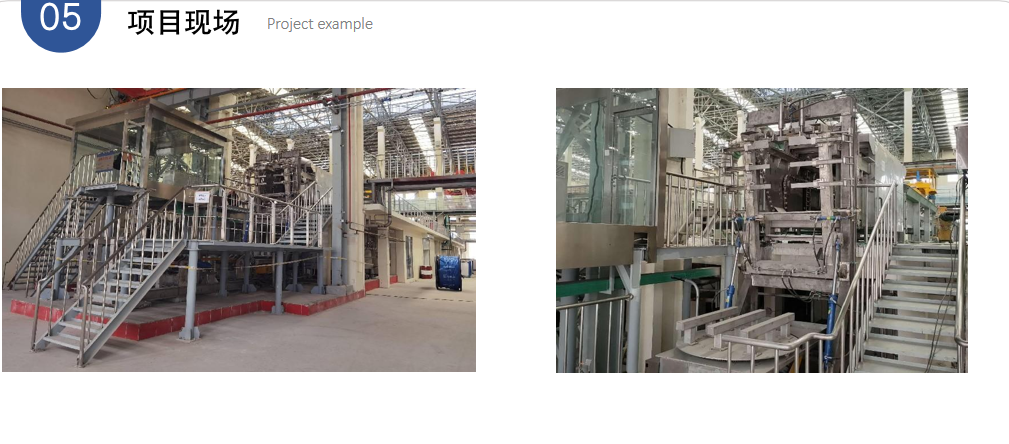

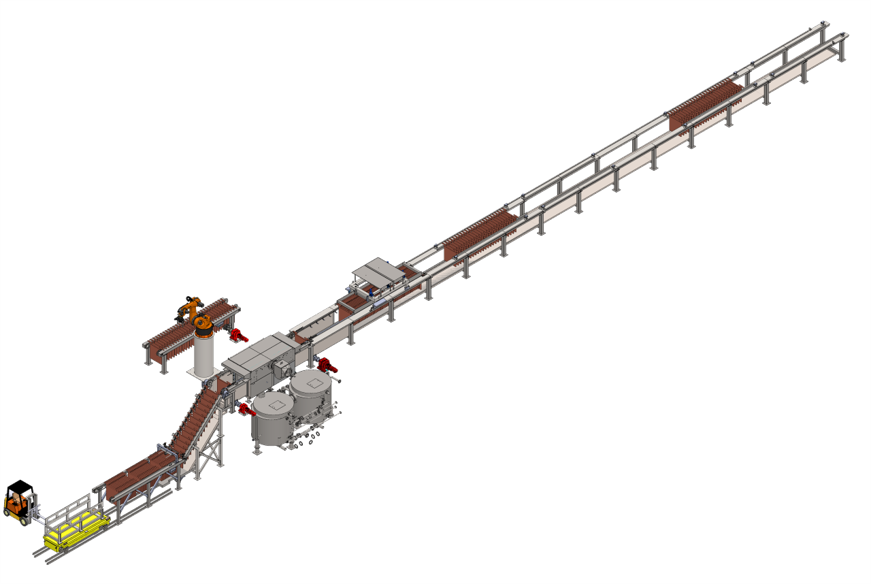

The equipment automates washing of post-electrolysis residues, including receiving, transporting, washing, drying, stacking, weighing, optional packing, output, and communication with dedicated cranes. It integrates mechanical and electrical functions and supports communication with smart factory control centers and DCS, enabling data upload of production reports, stats, history, and device status.

- Identification range

- identification decision

- statistic of attribute

- output mode

- 识别范围

- 识别判定

- 质量统计

- 输出方式

Pure and flawless! Efficient renewal! Stabilize the production line!

Residual electrode washing unit · Main classification

- Residual plate tilting 90-degree palletizing washing unit

The automated system handles post-electrolysis residue washing, including full-tank residue receiving, transport, washing, drying, stacking, weighing, optional packing, output, and dedicated crane communication, positioning, and logging. It integrates mechanical and electrical functions, supports smart factory control centers and DCS communication, and uploads production reports, statistics, history, and equipment status data.

- A functional washing unit for removing overweight plates from palletizing belts

The automated system cleans post-electrolysis residue, featuring full-tank residue receiving, transfer, transport, washing, overweight sorting, reject conveyor, drying, aggregation, flipping stacking, optional weighing, recording, reserved packing, output, and dedicated crane communication, positioning, and task logging. It integrates mechanical and electrical functions, supports smart factory control centers and DCS communication, and uploads production reports, statistics, history, and equipment status data.

- Residual plate suspended dense type washing unit

The automated equipment cleans post-electrolysis residue, with functions including full-tank residue receiving, transfer, transport, washing, drying, inclined descent, dense output, transfer rack, and dedicated crane communication, positioning, and task logging. It integrates mechanical and electrical systems, supports smart factory control centers and DCS communication, and uploads production reports, statistics, history, and equipment status data.